Description

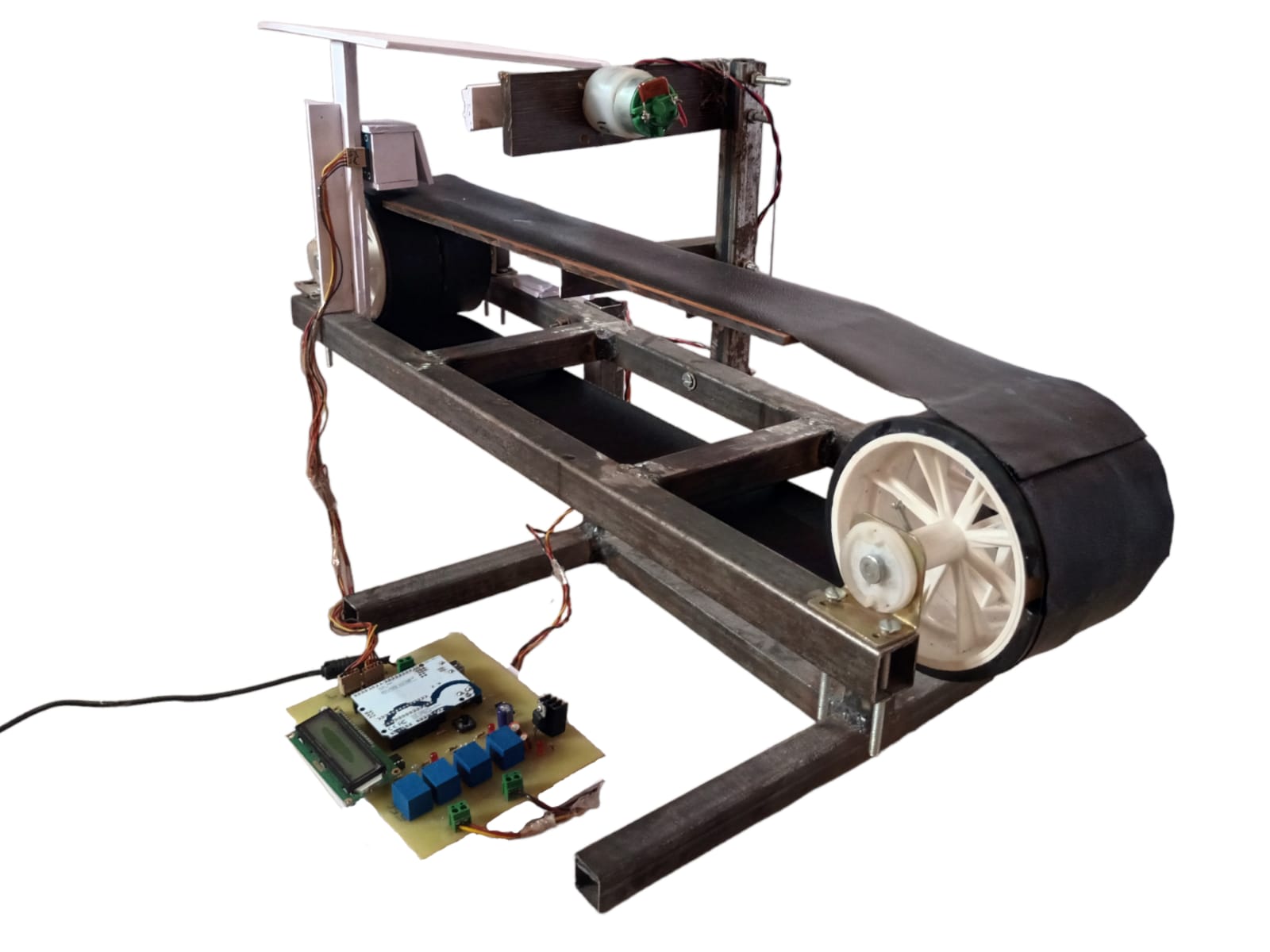

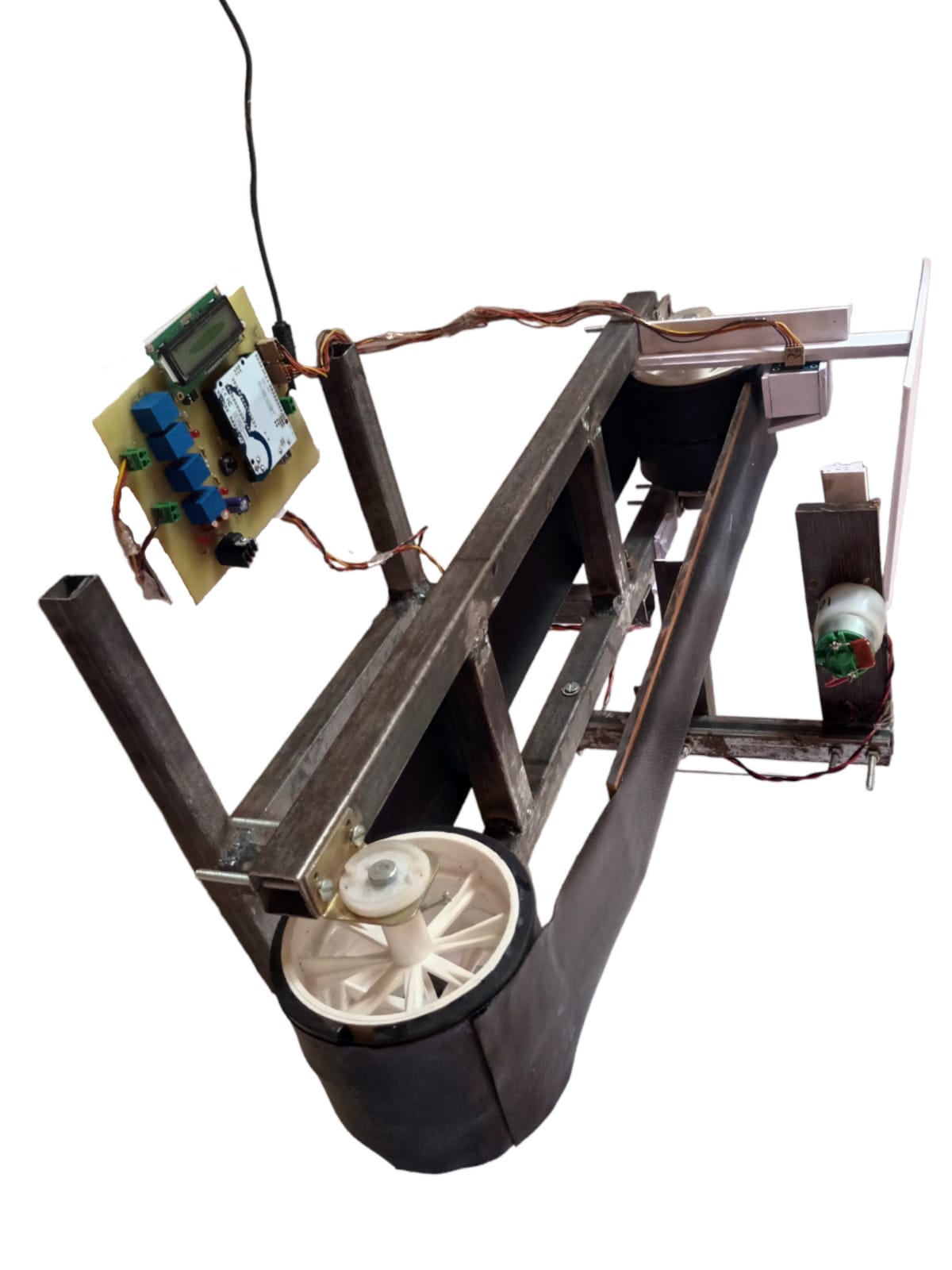

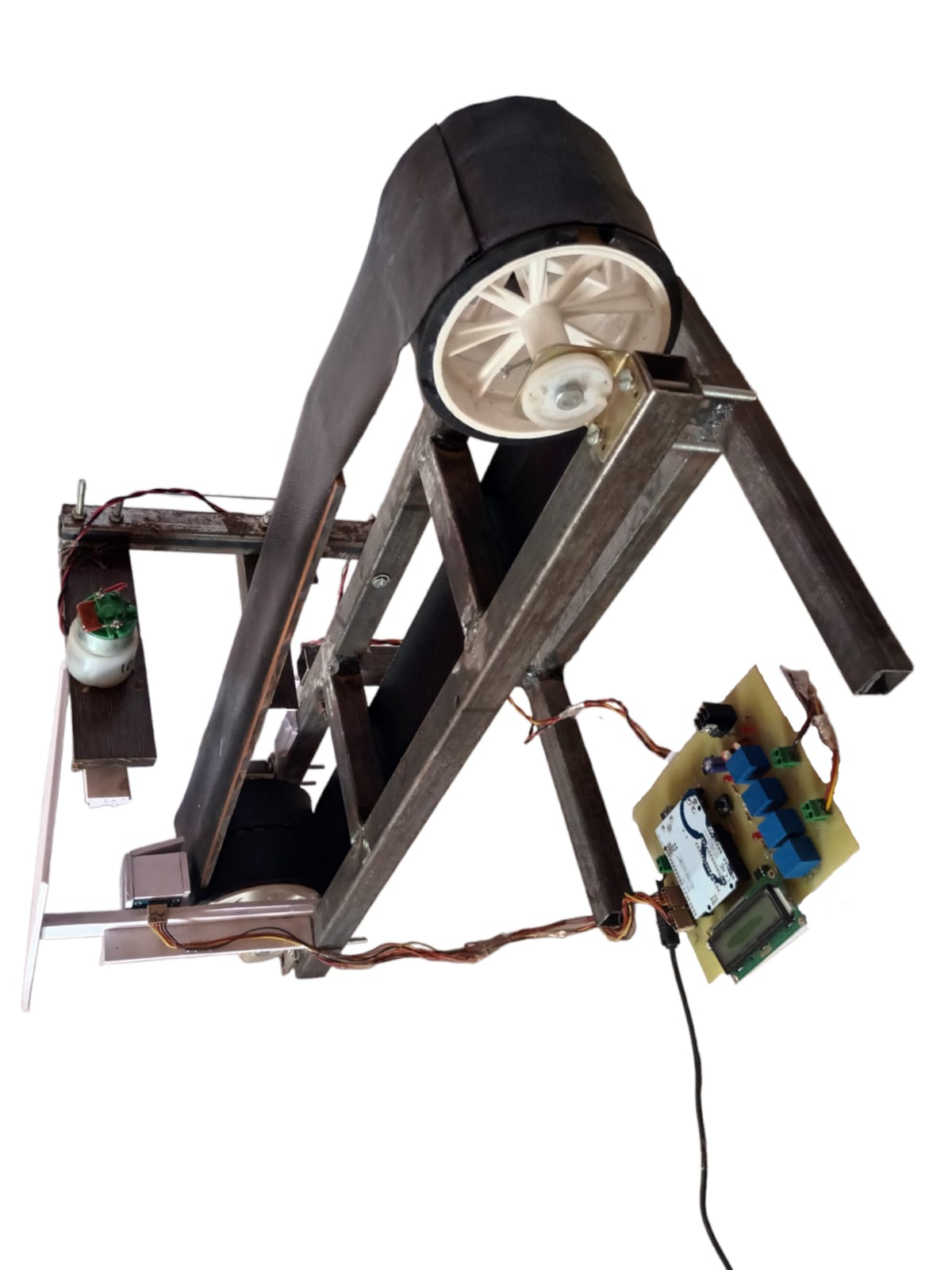

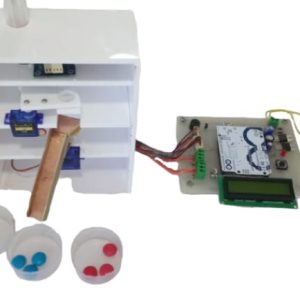

Sorting of products is a very difficult industrial process. Continuous manual sorting creates consistency issues. a working prototype designed for automatic sorting of objects based on the color. TCS230 sensor was used to detect the color of the product and the Arduino microcontroller was used to control the overall process. The identification of the color is based on the frequency analysis of the output of TCS230 sensor. conveyor belts were used, each controlled by separate DC motors. The belt is for placing the product to be analyzed by the color sensor, belt is for moving the container, having separated the all colours in the convey belt in order to separate the products. The experimental results promise that the prototype will fulfill the needs for higher production and precise quality in the field of automation.

Reduced performance, and cause challenges in maintaining product quality. An employee who has been performing an inspection task over and over again may eventually fail to recognize the color of product. Automating many of the tasks in the industries may help to improve the efficiency of manufacturing system. The purpose of this model is to design and implement a system which automatically separates products based on their color. This machine consists of three parts: conveyor belt, color sensor, and dc motor. The output and input of these parts was interfaced using Arduino. To reduce human efforts on mechanical maneuvering different types of sorting machines are being developed. These machines are too costly due to the complexity in the fabrication process. A common requirement in the field of color sorting is that of color sensing and identification

NOTE = Colour based sorting system using conveyer beltis the project of last year’s engineering projects, BE final year engineering project. This project is used for the BE last year’s mechanical department students. This project is mechanical project. This project ismechanical based project.

Colour based sorting system using conveyer beltis the project of a good price for the engineering projects. It is a very comparative engineering project. It is a very good BE final year project. It is a project forarduino based project. This project is sensors based project. This project is colour sensor based projects.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place for the degree final year engineering projects as well as for mechanical students’ final year for the golden opportunity.

Colour based sorting system using conveyer beltis an easy project and idea for the mechanicalbase students and 100% output is done.

HIGHLIGHTS

- For sorting object in industry optical sorting is very much convenient.

- The colour sorting machine is mainly a device that can sense the different colour of the object and assert them into their respective location.

- When object move to their respective location with the rotation of dc motor and convers belt Colour and size are the most important features for accurate classification and sorting of product which can be done by using some optical sensors.

- The system performed well as programmed and detects the object according to their Colour.

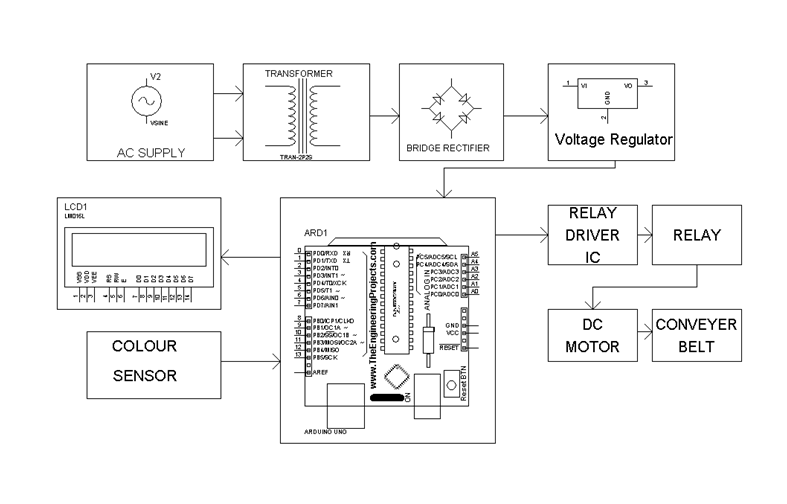

BLOCK DIAGRAM

block didram

HARDWARE REQUIREMENTS

- Transformer

- Bridge rectifier

- Voltage regulator

- Arduino

- LCD display

- Colour sensor

- Relay driver IC 2003

- Relay

- Dc motor

- Convery belt

SOFTWARE REQUIREMENTS

Arduino id

Eagle

Protious

varsha mohite –

good

Abhijit mane –

Excellent

sanjay kamat –

The project having One ready made kit and another one PCB and their required components. So, i have got a great Experience.

Bharat Khurape –

Received project within time and got quick and helpful support from staff