Showing 1–16 of 51 results

-

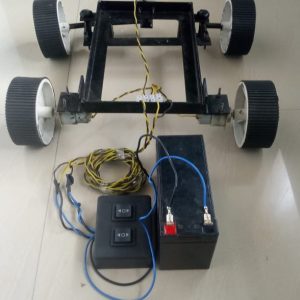

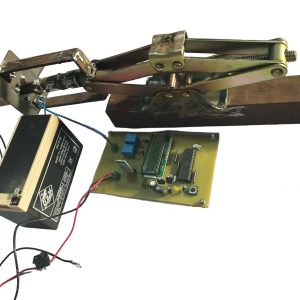

Android Controlled Car Jack

₹23,000.00₹22,000.00The project is designed to control the direction of car jack by using an android phone with the help of Bluetooth device. The direction of the DC motor is depending on the signal which is coming from mobile. Hence, if we press UP, this is present on your mobile then the relay1 & relay4 gets ON, so the motor rotates in forward direction. And if when we press DOWN from mobile the relay2 & realy3 gets ON then the motor rotates in backward direction.

-

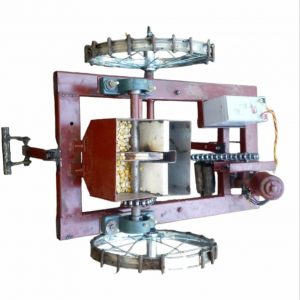

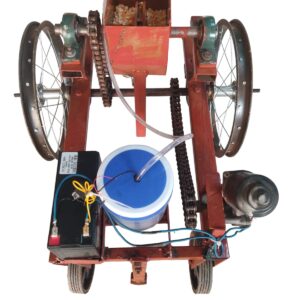

Automated Seed Sowing Mechanism

₹18,400.00₹17,400.00Presently farmers are facing shortage of labours due to growing industrialisation. To achieve required production in farms need to implement automation. This project aim at automation of manual seed sowing process. This robot consists Plough in front that digs soil. Covering plate covers seed with soil.

- -11%

Automatic Cradle

₹17,000.00₹15,200.00In this project we have implemented concept that helps mothers. It consists of Wet sensor it senses wet bed nature and alerts mother to change bed. and Mic sensor which senses crying sound of child sleeping in cradle and automatically starts swinging of cradle to make calm child.

-

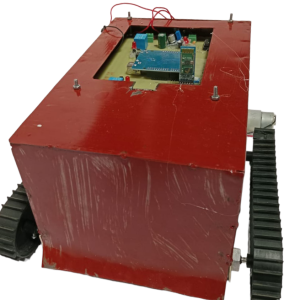

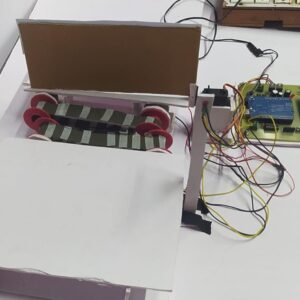

AUTOMATIC SOLAR PANEL CLEANING ROBOT USING ARDUINO

₹14,800.00₹13,800.00The Solar energy is the most abundant source of energy for all the forms of Life on the planet Earth. Solar is the basic source of renewable energy. One can generally assume a reduction of about 40% – 55%, if the panels are not clean properly for 1-2 months.

-

Automatic Solar Pannel Cleaning By Sensing Solar Voltage And Light Luminance

₹11,000.00₹9,400.00The solar PV modules are generally employed in dusty environments. The dust gets accumulated on the front surface of the module and blocks the incident light from the sun. It reduces the power generation capacity of the module. The power output reduces as much as by 50% if the module is not cleaned for a month.