Description

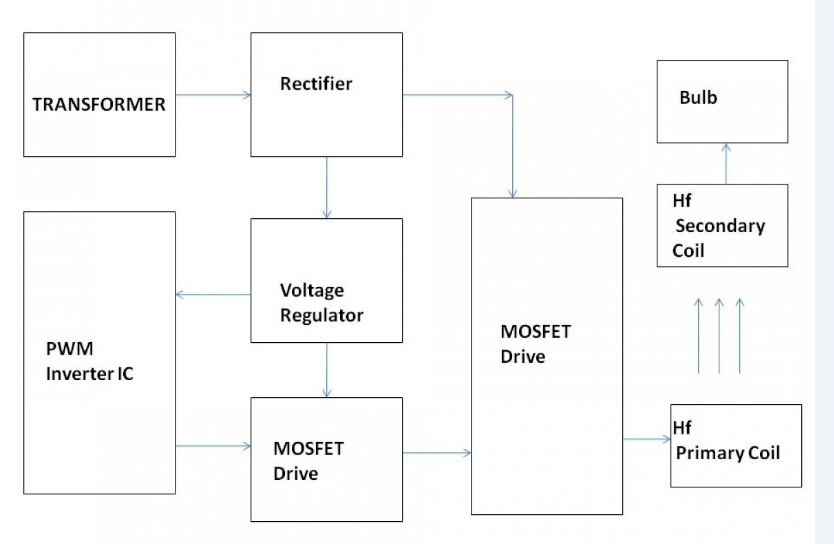

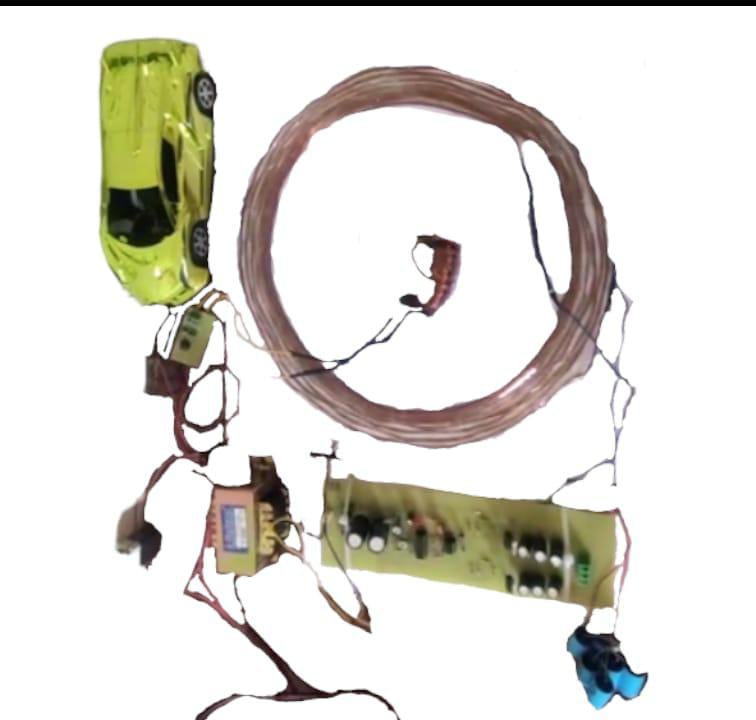

The main objective of this project is to develop a concept of wireless power transfer for several applications such as wireless powered electric vehicle in stores, airports, departmental stores etc. It can also charge a rechargeable battery or a cell phone wirelessly suitably modified for the purpose. AC 230V ,50 Hz mains is stepped down to low voltage ac by conventional 50 Hz iron cored transformer which is then rectified by a bridge rectifier to develop around 14 volt DC. This DC is again made to ac by a PWM inverter using half bridge concept comprising of 2 MOSFETs and 2 capacitors being switched at 40 KHz which is then fed to a resonating high frequency coil acting as primary of an air core transformer. Another matching resonating coil formed as secondary drives a lamp load of 10 watts spaced at an air distance of 20 CMs. The overall efficiency of the power transfer in this case is more than 90% for perfectly coupled and matched series resonators. However, practically resonators with a Q of 1,000 should be able to send power over a distance 9 times the radius of the devices with an efficiency of 10%. The secondary coil develops a voltage of 40 KHz at 12volt while it is kept spaced from the primary coil where air is used as the core. The output of the secondary can also be given to a high frequency bridge rectifier that can deliver DC which could then be regulated to maintain a constant voltage to a DC motor or current to feed to rechargeable battery or a cell phone. However, the overall efficiency of the power transfer shall be less than 50% for all such weakly coupled series resonators.

NOTE = Wireless power transformer by high frequency resonating coils is project of the last year engineering project, BE final year engineering project. This project is used for the BE last year department students. This project is used for the BE last year power electronics department student. This project is used BE last year electrical department students.

Wireless power transformer by high frequency resonating coils is the project of good price for the engineering projects. It is vary comparative engineering project.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place for the degree and diploma final year engineering projects as well as for electrical and power electronics students’ final year for the golden opportunity.

Wireless power transformer by high frequency resonating coils is easy project and idea for the electrical and power electronics degree and diploma base student & 100% output is done.

HIGHLIGHTS

- Wireless power transfer for several application

- Out put voltage is stepped down to low voltage

- 40khz is fed to resonating high frequency coil as primary

- Matching resonating coil formed secondary drive a lamp load of 10watt spaced distance 20cm

- efficiency of power transfer is more then 90%

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- MOSFET

- PWM inverter ic

- Coil

- Transformer

- Load (LED)

SOFTWARE REQUIREMENTS

eagle

Danish (Denmark) –

I Hired the hanayman conneection to assemble a disk for me the in home free estimate wss convenient and easy jos assembled my desk and went above and beyound i am so happy with the result and next time i have a project that reqaires a carpenter i will ask for him agin jos supper nice effeient and i felt making com fortable wiht him in my home he was very sweet to my two over friendly cast thank you joe for making my life easie

Bhargavi Dhonewadi –

Thank you Electrosal hi tech. They helped me a lot in my project work.once again thank you Electrosal team .

Maheshawar Sahu –

Great place.

The place where you can change your ideas in real working prototypes & machines.

It is one of your project manufacturing small scale industry in the area.

Lohith Royal (bengalore) –

Online customer support by the electrosal support team is quite promising. They attended me and solved my doubt each time I made a video call.

Nikhil dhuriya –

Nice Customer Support. Thanks For Online Video Call Support.