Description

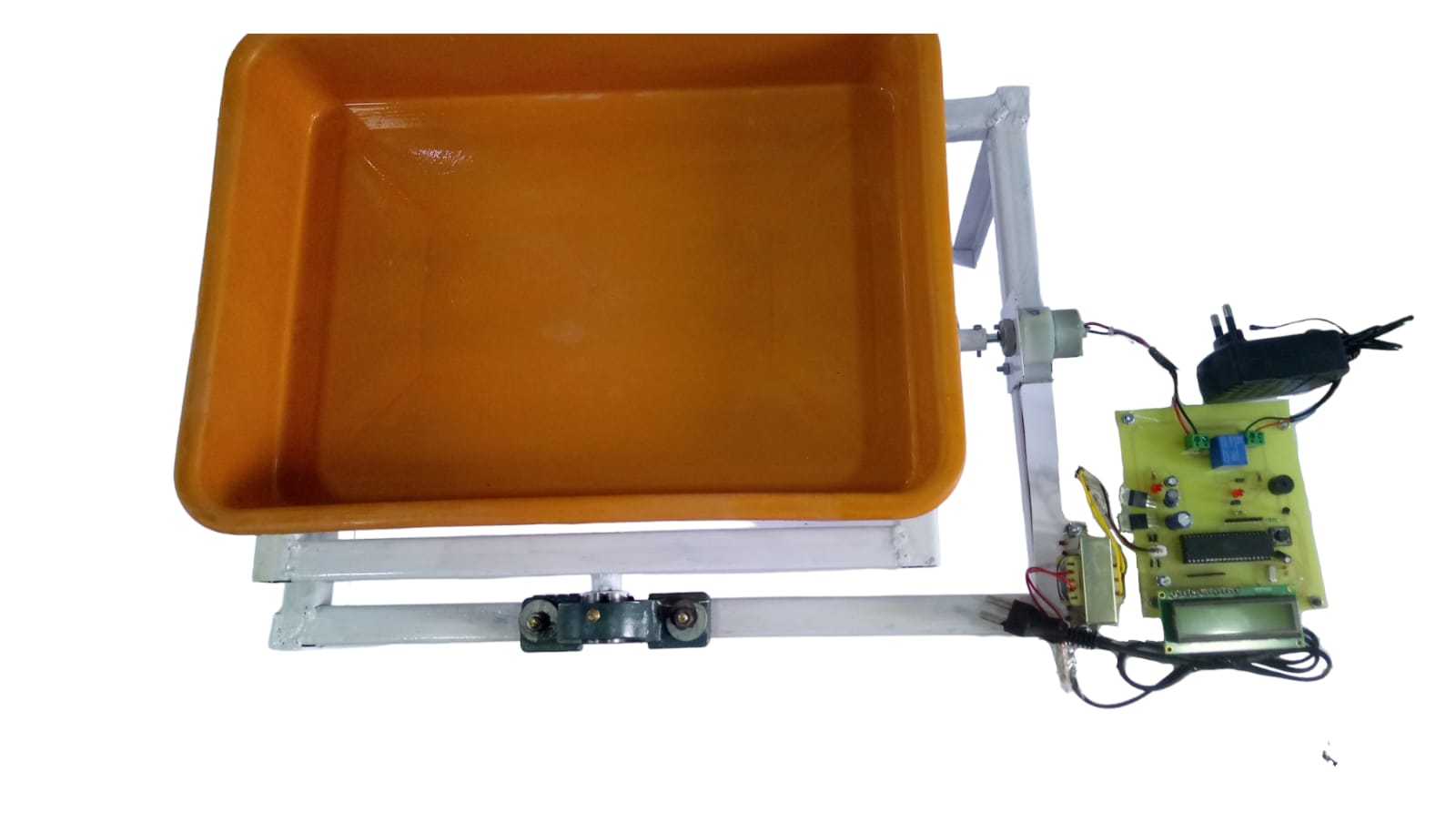

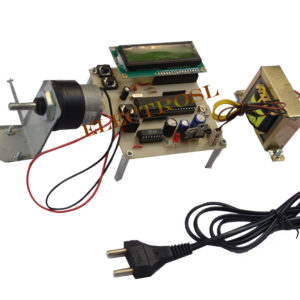

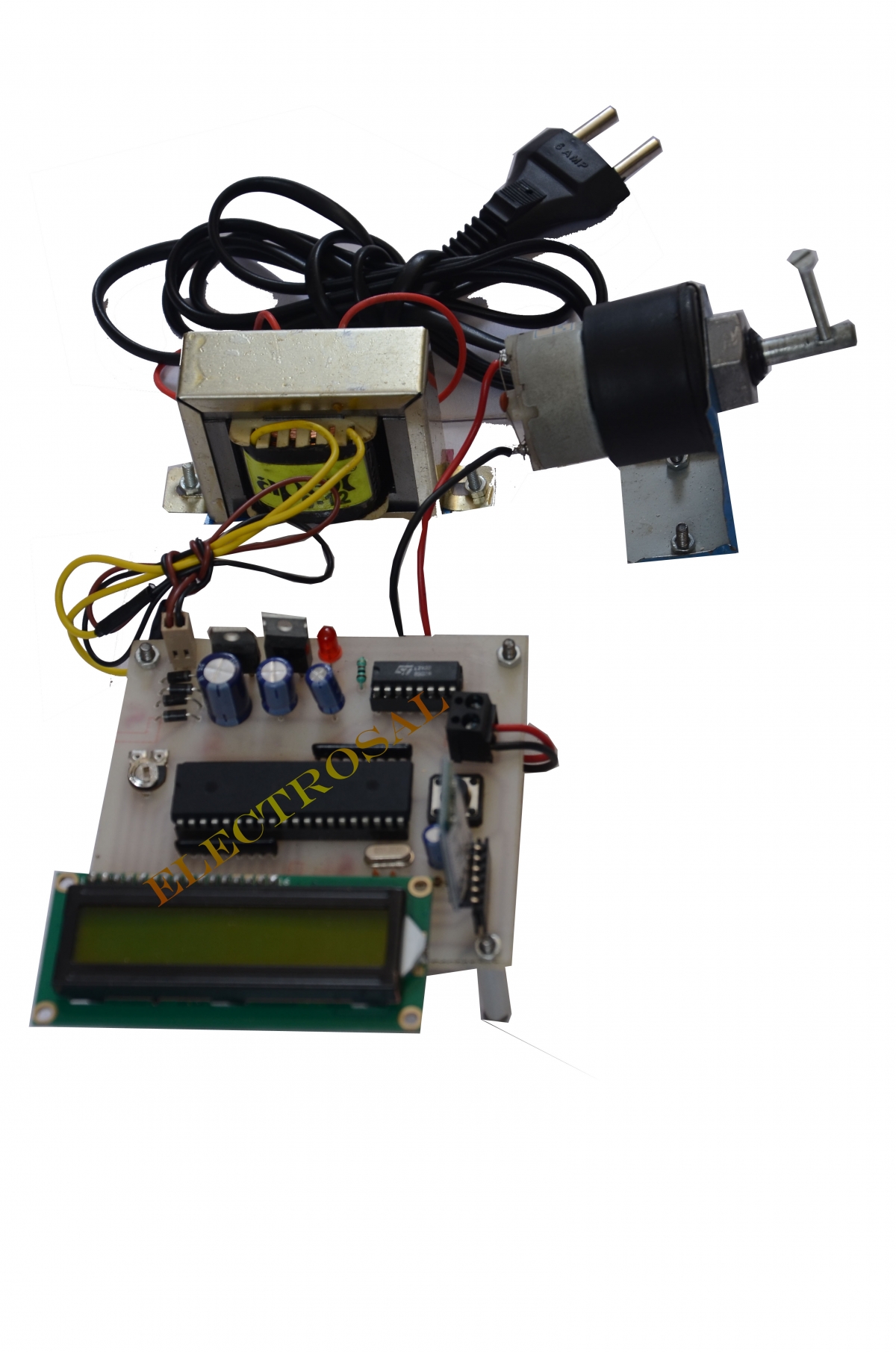

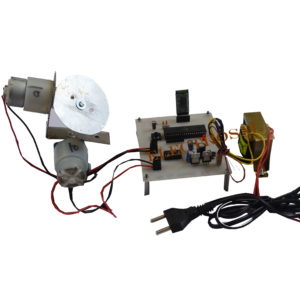

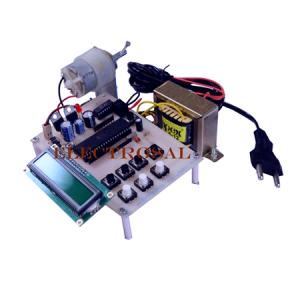

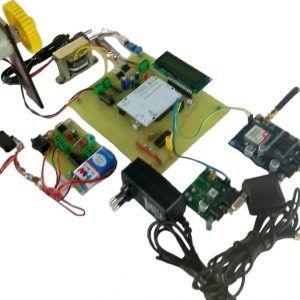

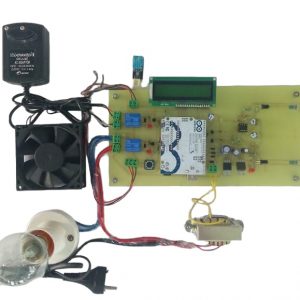

Etching is a “subtractive” method used for the production of printed circuit boards: ferric chloride acid is used to remove unwanted copper from a prefabricated laminate. The main objective of this project is, you can etch a PCB by yourself, in a lab or even at home, through a simple and inexpensive production process. This project is made up of with arduino UNO, LCD display, voltage regulator circuit, relay and dc motor. To produce a single or a very small number of boards and want to avoid manufacturing costs.

The etching process is therefore effective for a small workshop. For 10-20 number of PCB’s there is not necessary for go towards big tanks. Because in small scale industries, it is not affordable. This is done by applying a temporary mask that protects parts of the laminate from the acid and leaves the desired copper layer untouched. For this project, we are set the time of 30mins. So after completion of 30mins the machine gets OFF. After completion set time, we will get the clean PCB. If you are doing etching manually, then it will take long time as well as manually etching was not accurate and also the thickness of tracks will not be constant so the quality of PCB gets reduced. So to avoid these problems you can use this “Small scale automatic etching machine”. After completion of set time buzzer will beep and machine will stops its motion. Finally you will get well finished PCB.

Note add-

Small scale automatic etching machinethis project for the good price for the engineering projects. It is very comparative engineering project. It is very good project BE power electronics project student is use. For the project is the embedded base project and core electronics base project. This project is electrical based project,

Small scale automatic etching machinethe microcontroller based project for the good project, excellent project for the BE last year engineering student is use for the student is use core electrical student is use. This project for the competitive project in the BE electrical based project of the last year engineering student for the core electrical is use.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place of the degree and diploma final year engineering projects as well as electrical student is use. This project is power electronics based project and microcontroller based project.

Small scale automatic etching machinethe best projects of the embedded base for the power electronics ,in final year student is use and idea for the and degree and diploma base students and 100% output is done.

HIGHLIGHTS

- Etching is a “subtractive” method used for the production of printed circuit boards: ferric chloride acid is used to remove unwanted copper from a prefabricated laminate.

- The main objective of this project is, you can etch a PCB by yourself, in a lab or even at home, through a simple and inexpensive production process.

- To produce a single or a very small number of boards and want to avoid manufacturing costs.

- The etching process is therefore effective for a small workshop.

- After completion of set time buzzer will beep and machine will stops its motion. Finally you will get well finished PCB.

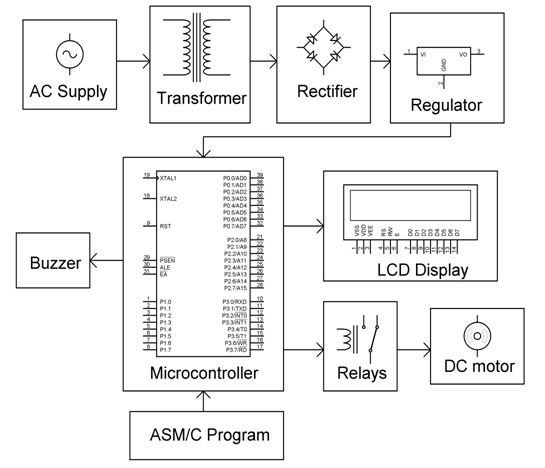

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Microcontroller

- LCD display

- Buzzer

- Voltage regulator circuit

- DC motor

- transformer ,

- voltage regulated circuit ,

- relay

SOFTWARE REQUIREMENTS

- Keil uVision 4

- Eagle

- proteus

Ankita shinde –

Good

Gouri Talvar –

Yesterday i received my DC MOTOR WITH PWM SPEED CONTROL IN ALL FOUR QUADRANTS USING MICROCONTROLLER project kit.. kit had all the components and parts as mentioned in component lists. Looking forward to start working on it.