Description

The main aim of the project is to process the real time acquisition under programmable logic control for large scale remote industrial environment.

In large industrial establishments many processes go on, therefore it is essential to monitor all the processes and control the factors affecting them. Adapting a technology like PLC (programmable logic control) one can achieve the above mentioned objective effectively, and thus saving a lot of manpower.

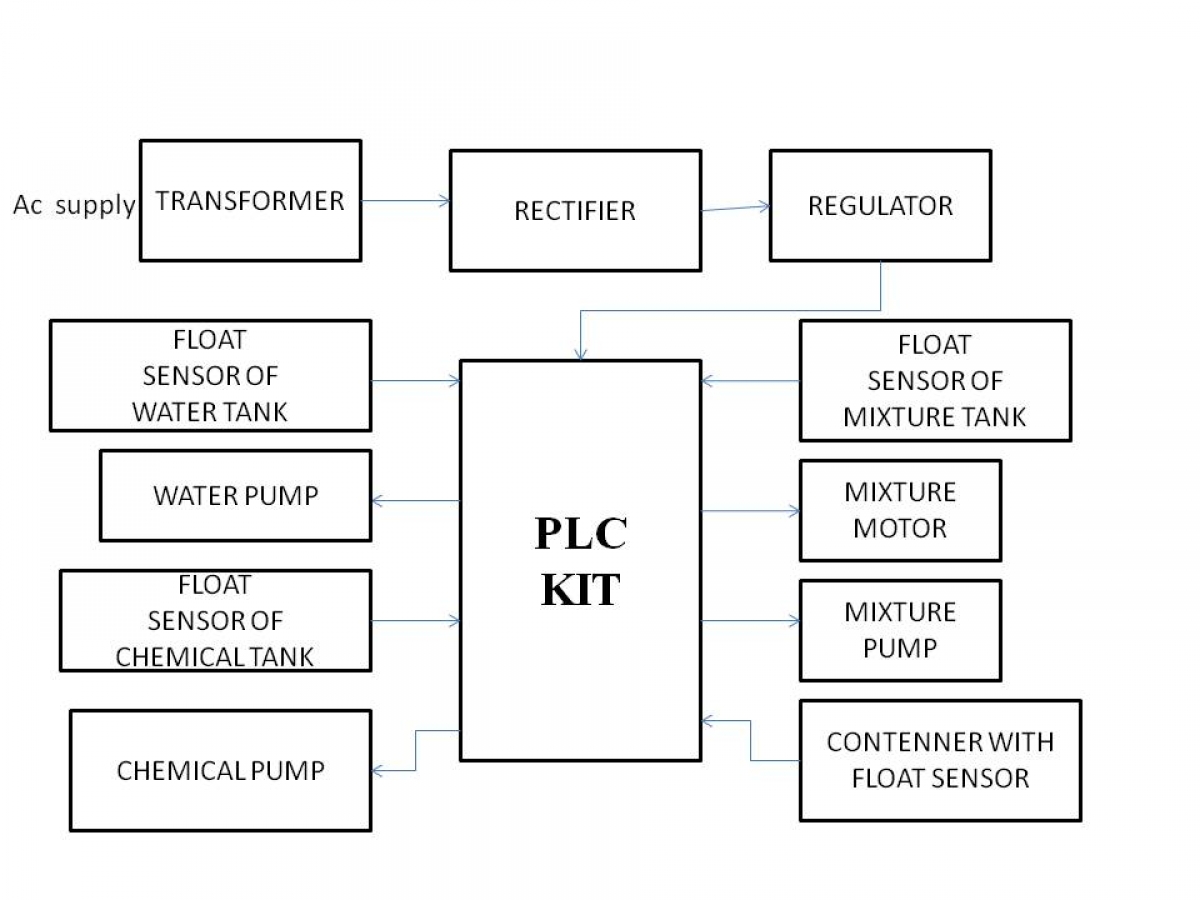

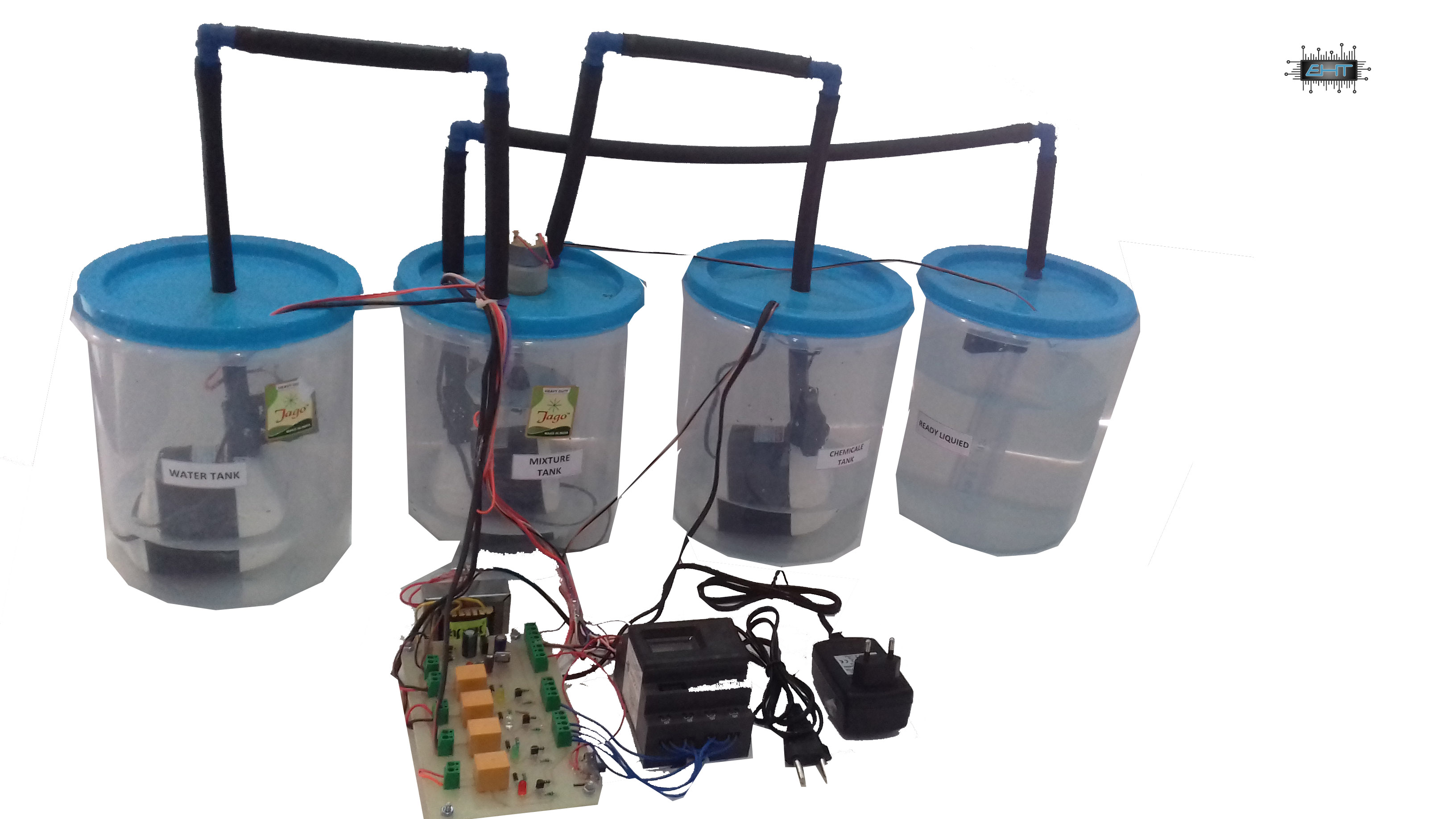

For achieving this real-time scenario, This system for a automatic plant operation is taken. Here float sensors are interfaced to the controller. signalcollected from the float sensors are constantly sent to the PLC controller which is in turn logically programmed. At the top side of PLC controller given all the input signals. When the float sensor, sense set point the PLC controller sends a command to the corresponding relay. The water pump and motor connected through relay contacts (corresponding to their sensors) are turned OFF (or ON in vice versa). High limit and low limit features are available.

Hence, processes at hazardous areas can be controlled with more accuracy and better safety using PLC Controller. Adapting such a technology will save both money and time.

HIGHLIGHTS

- This project is real time acquisition under PLC

- In large industrial establishment many processes go on

- This system for automatic plant operation is taken

- signalcollected from the float sensors are constantly sent to the PLC controller which is in turn logically programmed

BLOCK DIAGRAM

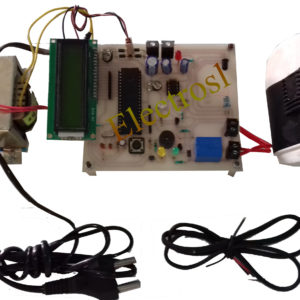

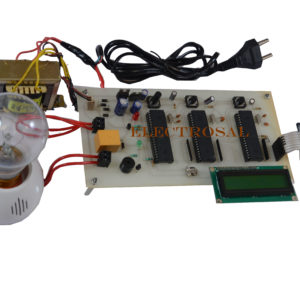

HARDWARE REQUIREMENTS

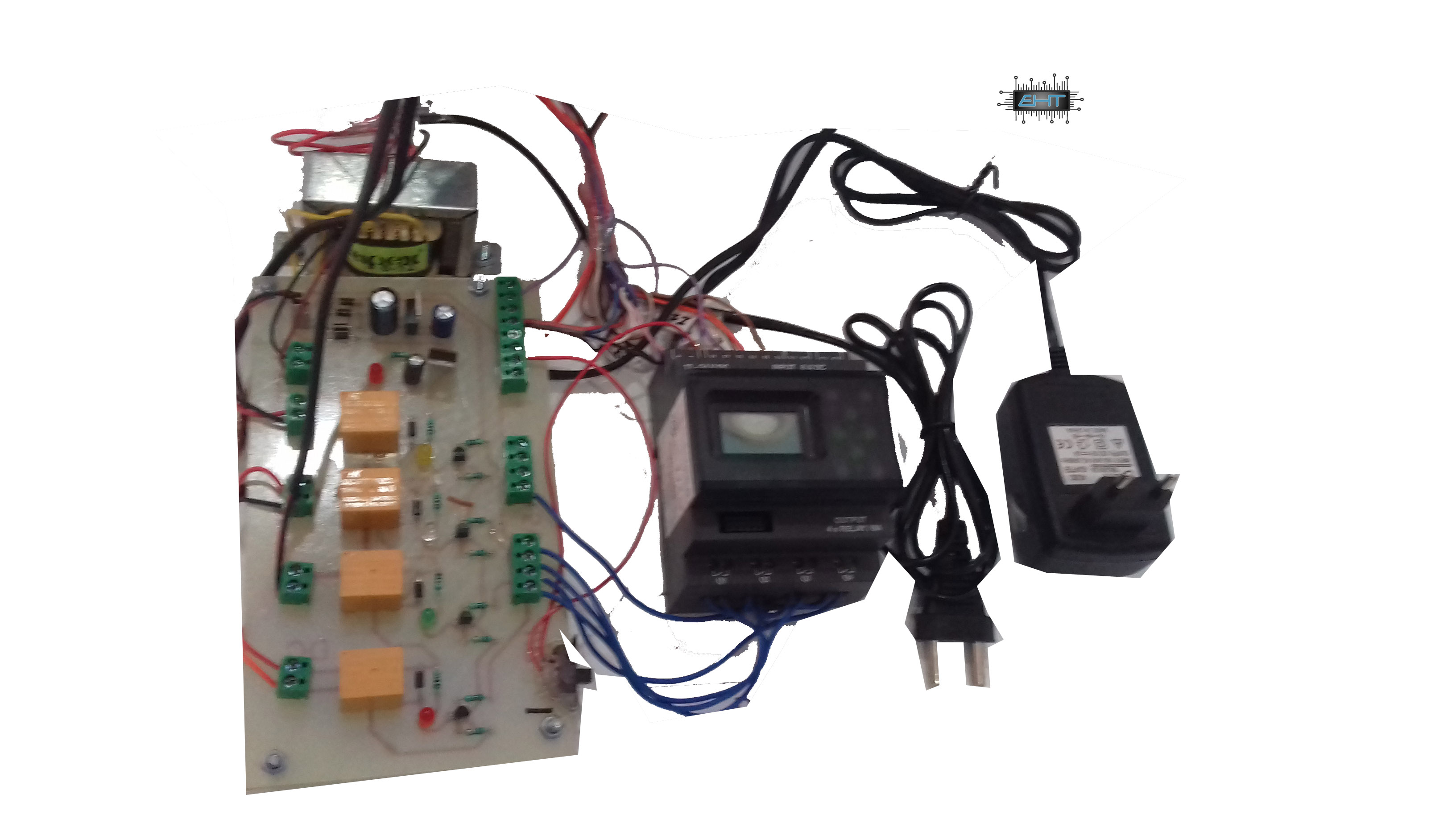

- PLC KIT

- Relay

- submersible pump

- Float Sensor

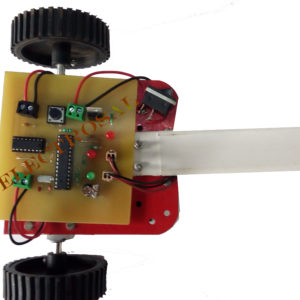

- DC Motor

- Pipes

- Tanks

- Transformer

SOFTWARE REQUIREMENTS

- G-softnx

- Eagle

Richa –

I’m purching this project This project is very good and output very good .and electrical team is sported me. Thank you Electrosal team

Tushar salvi –

The project having One ready made kit and another one PCB and their required components. So, i have got a great Experience.