Description

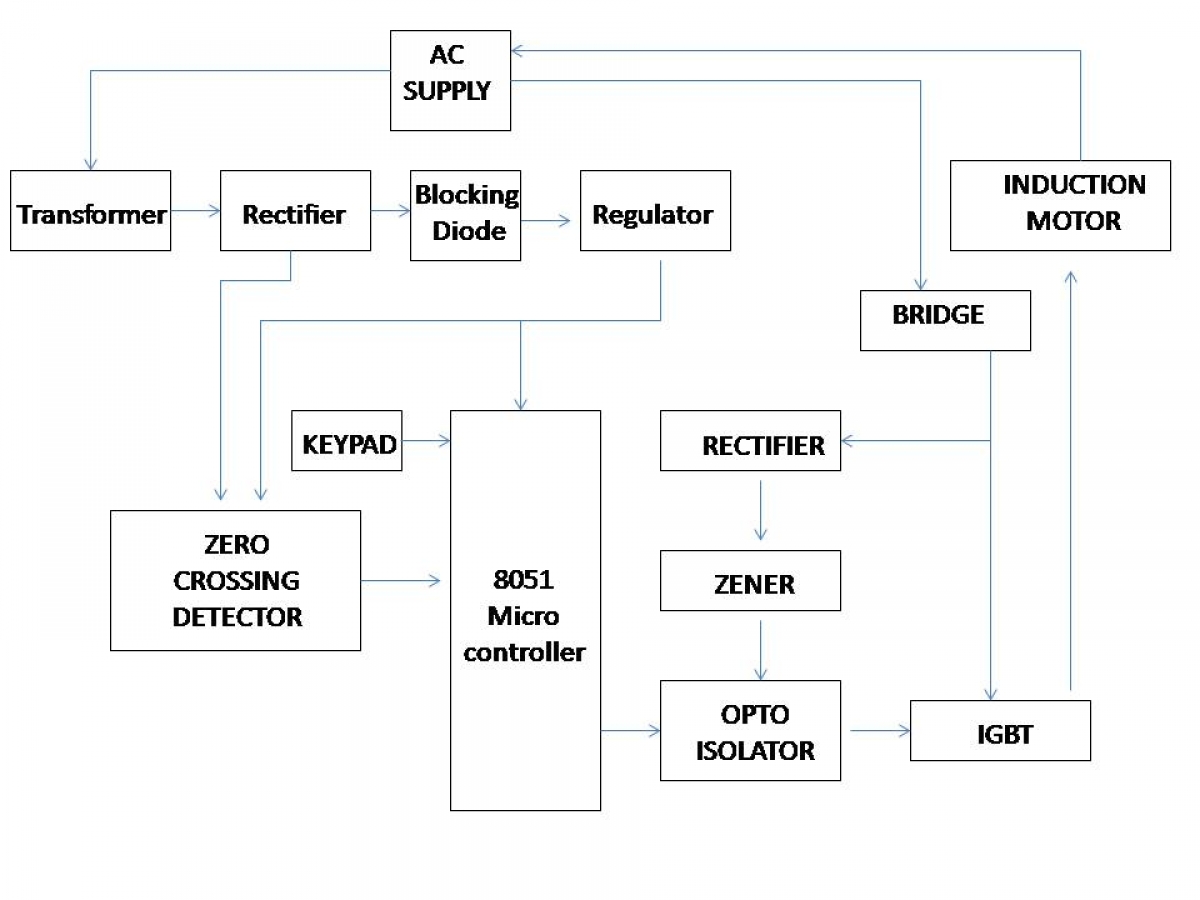

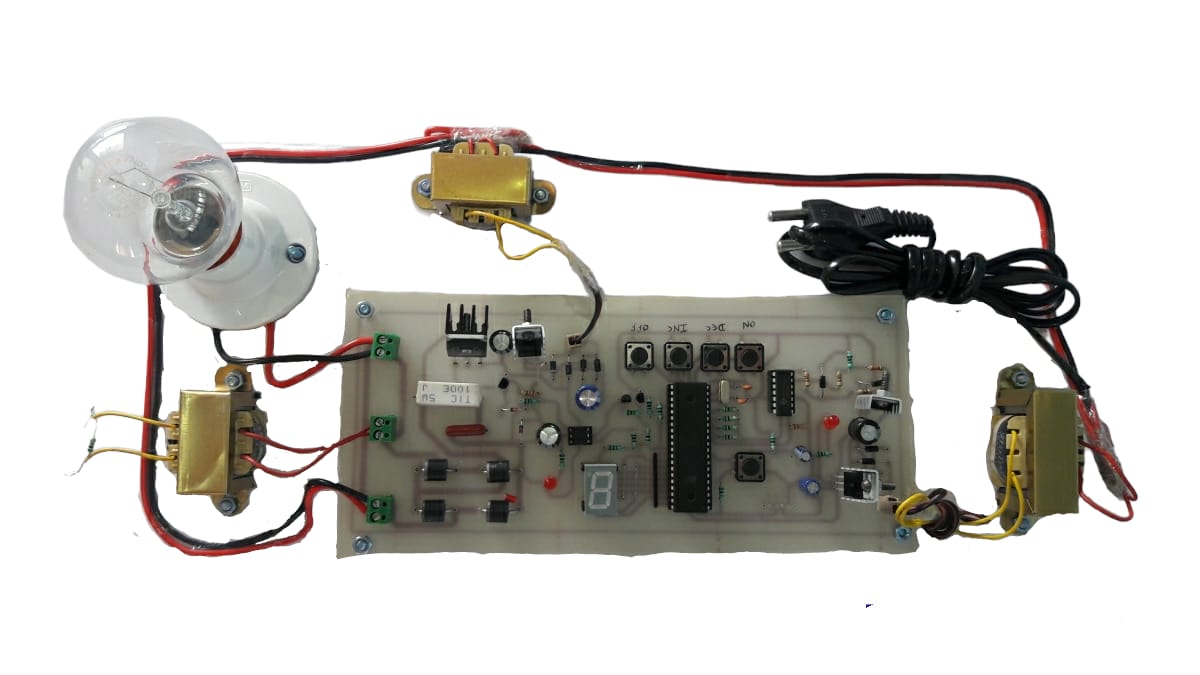

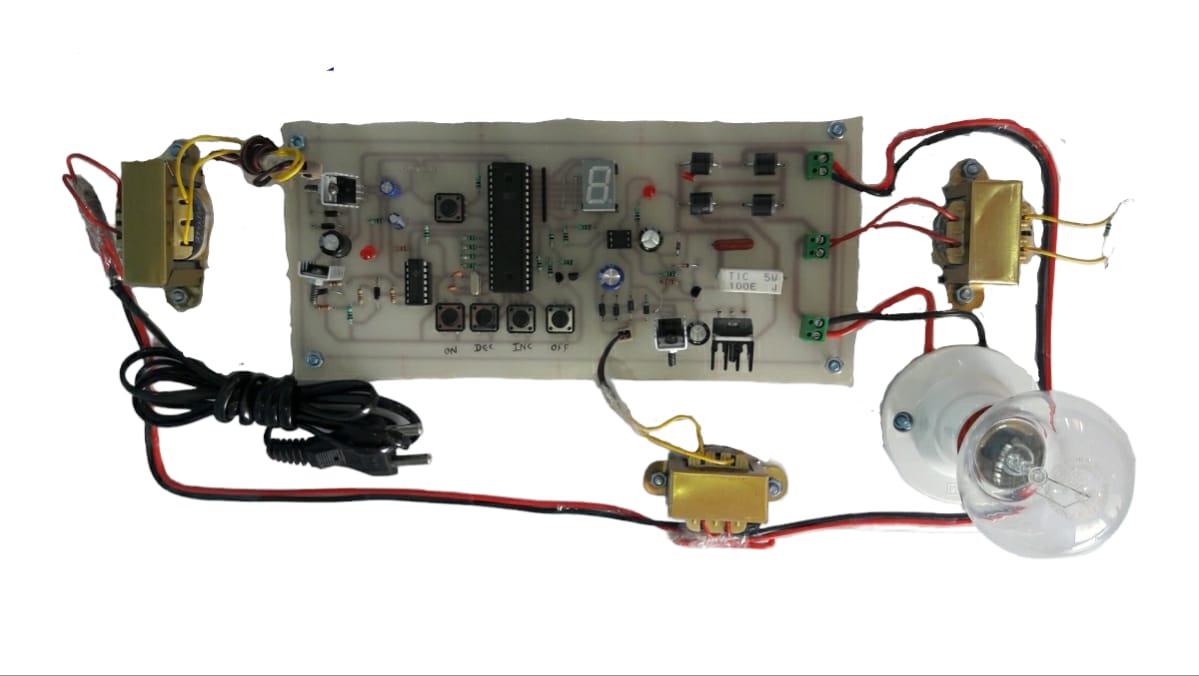

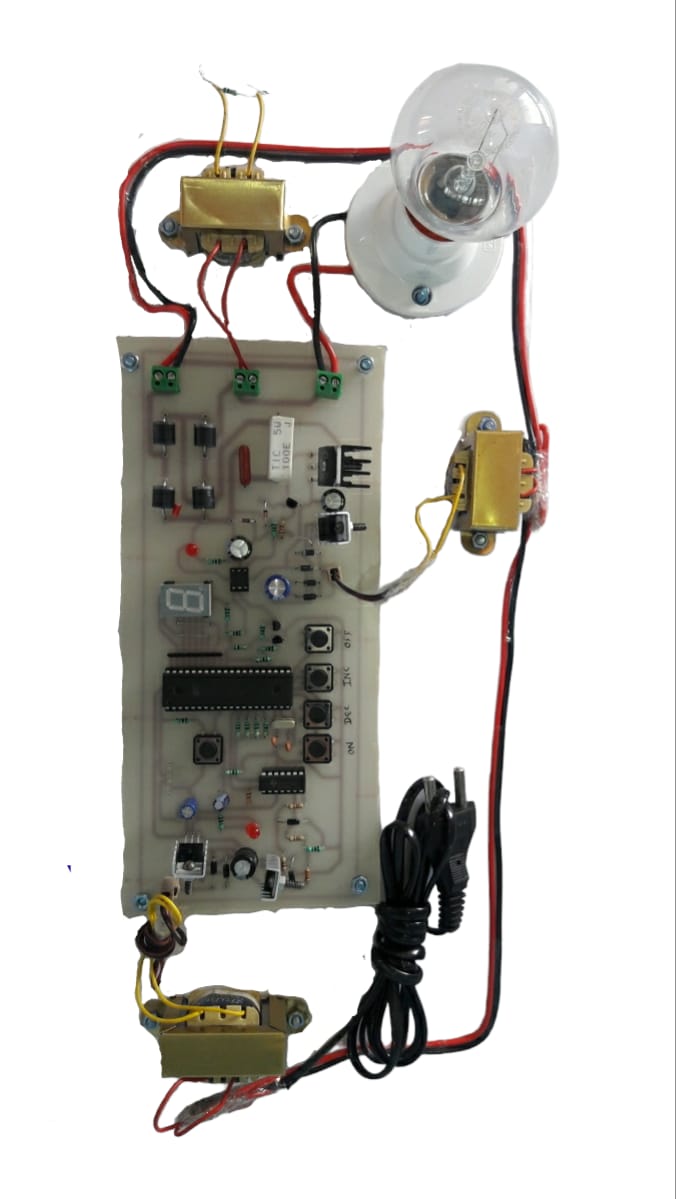

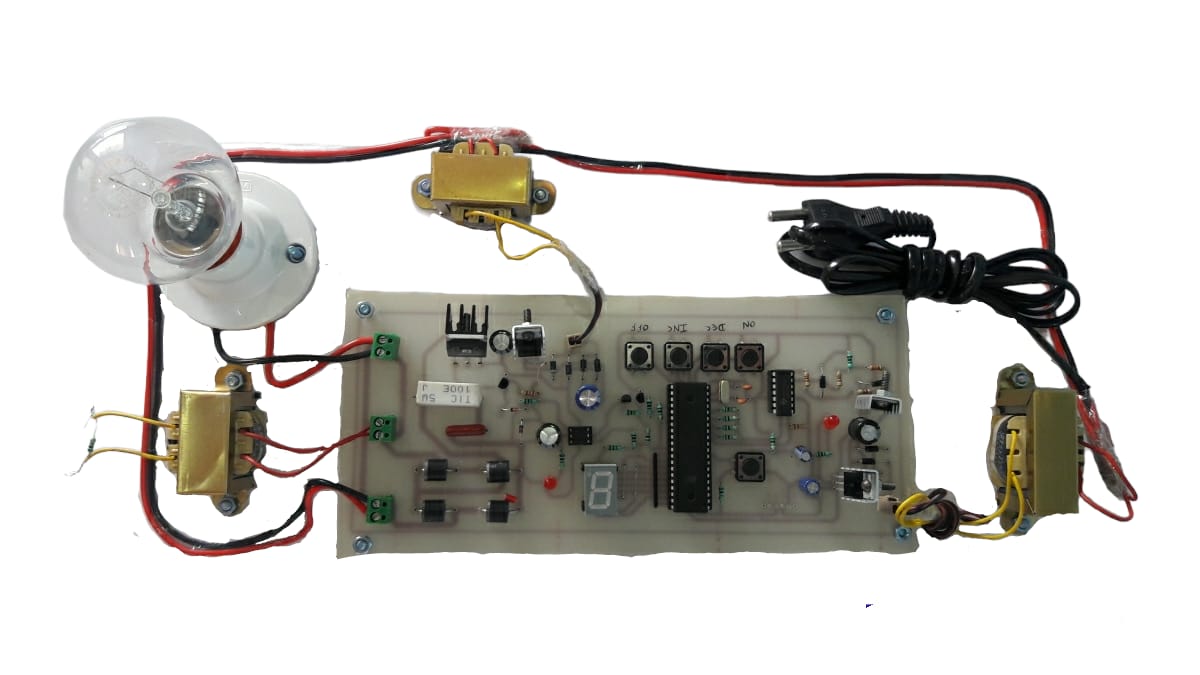

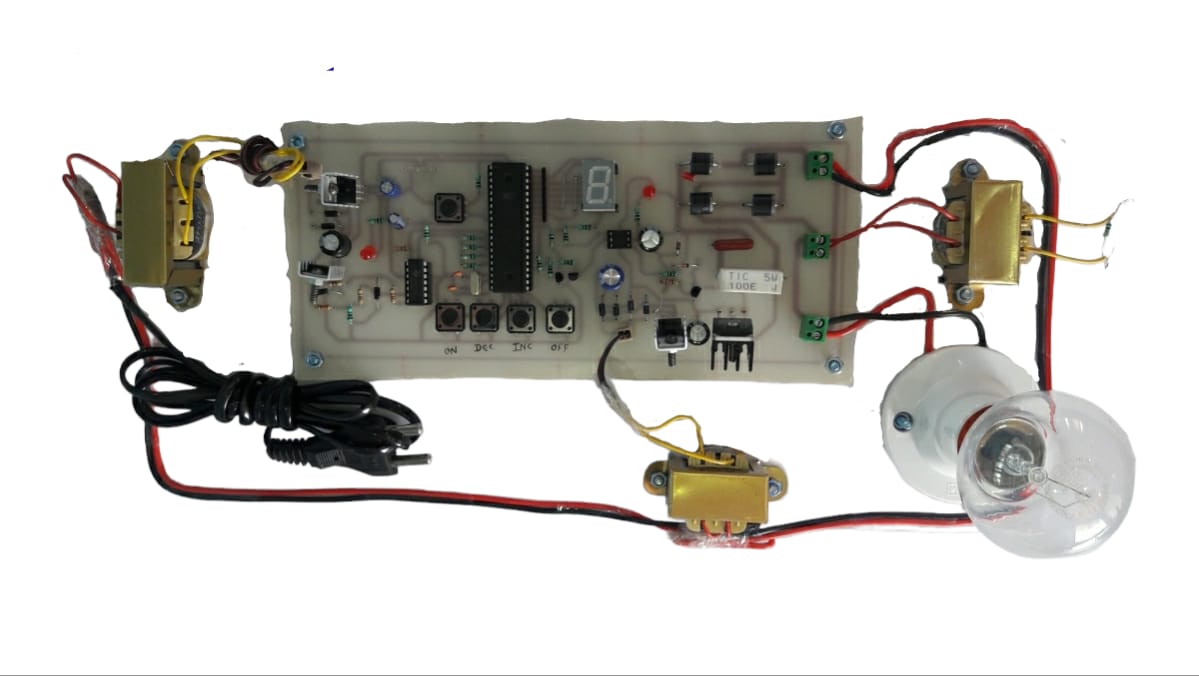

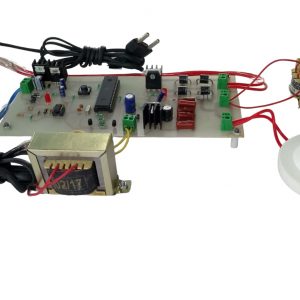

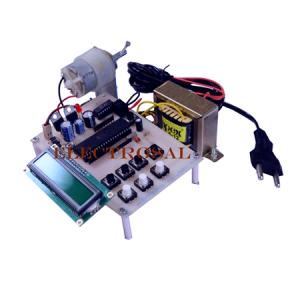

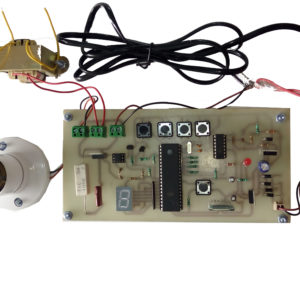

This project attempts a new speed control technique for the single-phase a.c. induction motor. It presents a design of a low-cost; high-efficiency drive capable of supplying a single-phase a.c. induction motor with a PWM modulated sinusoidal voltage. The circuit operation is controlled by an 8051 family microcontroller. The device is aimed at substituting the commonly used triac phase angle control drives. The circuit is capable of supplying a single-phase a.c. induction motor (or general a.c. inductive/resistive load) with varying a.c. voltage. The same as in triac control, the voltage applied to the load can be varied from zero to maximum value. On the other hand, it uses a pulse width modulation technique (PWM), and when compared with the phase angle control used for triacs, produces much lower high order harmonics. Thus, it suits EMC/EMI regulations much better. Because the circuit is aimed at low-cost, low/medium-power applications, it does not use a conventional converter topology to produce the output voltage waveform. It directly modulates the mains a.c. voltage. Compared with costly converter, it requires a lower number of active and passive power components. In summary, the device attempted here takes advantage of both the low price of the phase angle control and the low harmonic content and high efficiency that we can get with standard converter topology. The drive uses a PWM controlled MOSFET and the load in series with a bridge rectifier. This drive based on this new control technique is targeted for use in consumer and industrial products: washing machine, dishwashers, ventilators, compressors, and wherever the system cost is a consideration.

The input terminals of the rectifying bridge are connected in series to the load. The output terminals (rectified side) has a power transistor (IGBT, MOSFET or bipolar) connected across them. When the power transistor is off, current cannot flow through the rectifying bridge and the load which is in series remains in an off-state. When the power transistor is on, the bridge output terminals are short-circuited, then current can flow through the rectifying bridge and thus through the load. Thus by changing the duty cycle of the PWM pulses the power to the load is controlled. Special care is taken in the circuit such that the PWM pulses are synchronized with the supply phase by zero voltage sensing points.

HIGHLIGHTS

• This project is for speed control technique for the single-phase a.c. induction motor

• An 8051 family microcontroller used.

• PWM technique

• MOSFET are used.

• Applications- washing machine, dishwashers, ventilators, compressors,

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- 8051 family microcontroller

- MOSFET

- Bridge rectifier

- Single-phase A.C. induction motor

- Transformer

- ZCD

SOFTWARE REQUIREMENTS

- Eagle

- keil

- proteus

Chandan Debnath, West Bengal(India) –

I have purchased a project from electrosal basically i am afraid as it was the first time i purchased kit online after receiving i was very much satisfied with the kit. And also technical team support was excellent.

Pooja Tibile Belgaum(Karnataka) –

i received my SPEED CONTROL OF INDUCTION MOTOR USING ACPWM kit yesterday, the kit have all the components and parts as mentioned which are pretty exciting. Looking forward to start working on it.

Omkar Jadhav Pune(Maharashtra) –

Nice Project.

Govind Vishwakarma Madurai(Tamil Nadu) –

I have Ordered SPEED CONTROL OF INDUCTION MOTOR USING ACPWM project from electrosal.com And Assembling of the electronic system is easy with the help of the working demo videos and video call support, nice for electronics beginners.

Khushboo Thakur Skardu(Jammu and Kashmir) –

Had ordered SPEED CONTROL OF INDUCTION MOTOR USING ACPWM project. I have Ordered Doit Yourself Kit for this.Also there was a Working Video on your Website and also Nice Video Video call Support.A nice learning experience.

Aakash Salavi –

It was a good experience with u.. the teaching staff’s are too good..they were nice and friendly with us..and got a good knowledge abt arduino and pcb designing

Sunita Patil –

Well i got the ARDUINO BASED UNDERGROUND CABLE FAULT DETECTION project and i was surprised to see it delivered in such a good condition. I was afraid that sending a delicate circuit in through international shipping may damage it, but their packaging is extremely good.

Pranjale Hegade –

It was a good experience with u.. the teaching staff’s are too good..they were nice and friendly with us..and got a good knowledge abt arduino and pcb designing

Mayur Kharat –

Very much dedicated , highly skilled team of engineers . Can get the required project at an affordable price in the promised time.

The most important part is after sale service which is very much admirable

Aslesha Zunjar –

yesterday i received my ARDUINO BASED UNDERGROUND CABLE FAULT DETECTION project kit.. kit had all the components and parts as mentioned in component lists. Looking forward to start working on it.

M S K Digital New –

I saw this project video on youtube and desided to purchase this kit. I got this kit in time with in good condition. With the help off eplanatory video I can understand all concepts easily.

Vidhya Sonule –

As a 3rd year diploma student, I was very pleased with this project. The package was delivered on time and in complete working condition.thank you Electrosal.

Riya Mohite –

Very Good

Nandkumar Parit –

Good project and best service

Qasim (traq) –

A great level of detail and understanding from these guys. I come from a power background personally, so I struggled a little with an electronic based project. However, Electrosal made this seamless. Through, easy communication and extremely compotent professionals. Highly recommended thanks.

Alok Kumar –

My kit delivery was a day late but no problems since my submissions were late, well I surely learned a lot from this kit it has very detailed explanation documents and videos. Overall a nice experience

Rima Kallingal –

The project quality was very good, I like the way they provide all system development videos along with the kit. I had ordered the AUTOMATIC POWER FACTOR CORRECTION USING ARDUINO kit & am happy to have ordered from here.. no issues at all

Retan Setu –

The online explanation system for my software project kit was wonderful. I saw it 3 times and once again before my final presentation, gave me detailed knowledge of the opinion mining project I bought.

Rahul Jadhav –

Nice Project

Shital Patil –

My friend told me of these kind of kits available at electrosal.com and i ordered the FINGERPRINT BASE BIKE START project. the system is just amazing use of technology. Their tutorials and online support provide sufficient practical knowledge.